Between operating heavy machinery and securing steel components into place, steel erectors take on a significant amount of risk as part of their day-to-day job.

What can they do to reduce the risks?

Fortunately, the Health and Safety Executive (HSE) has put together clear health and safety guidance specifically designed for steel erectors working in the construction industry.

Below, the experienced trainers and assessors at SB Skills Solutions break down six key health and safety challenges and how to overcome them.

Broken down into six straightforward steel erector health and safety challenges, the experienced team of trainers and assessors at SB Skills Solutions explains each challenge in detail below and how you can overcome them.

What are the six steel erector health and safety challenges?

Regardless of whether you’re already working as a steel erector, or are considering a move into the construction industry, getting to grips with the health and safety challenges is essential.

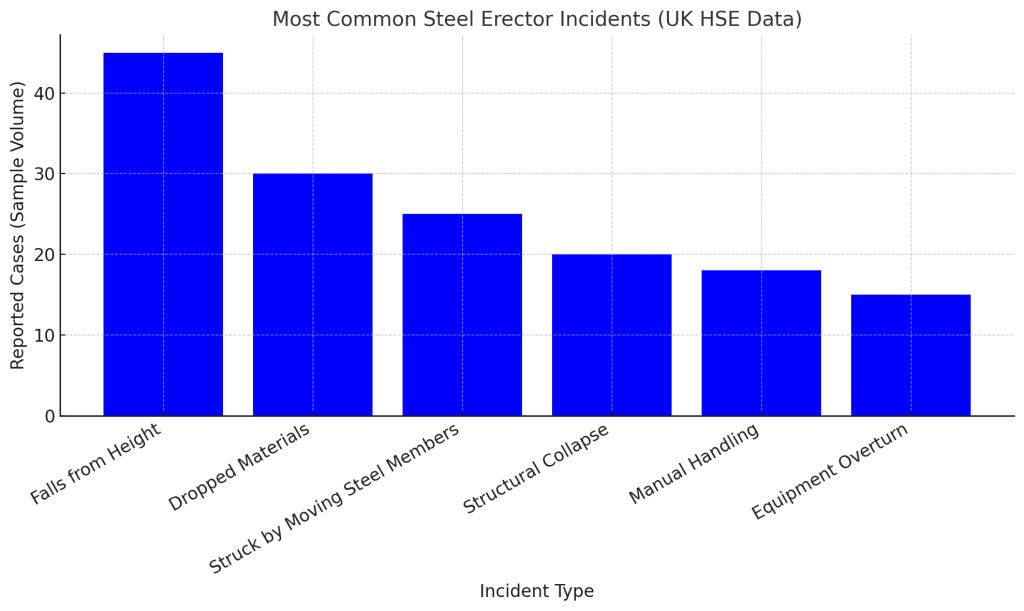

According to the HSE, there are half-a-dozen key health and safety challenges for steel erectors.

1. Falls from height

Challenge

Naturally, steel erectors often work at height when assembling the framework for buildings and other structures. However, working at height comes with the risk of falling which can result in anything from a few minor bruises and soft tissue damage to serious fractures and in more severe cases, death.

Solution

To combat this challenge, steel erectors should first attempt to eliminate completely the need to work at height.

If this isn’t possible, then mitigations should be considered to reduce the potential impact of a fall.

These steps might include:

- Introducing working platforms, such as scaffolding or mobile elevating work platforms (MEWPs)

- Learning how to safely ‘straddle’ beams where work platforms aren’t suitable

- Adding fall protection in the form of nets, twin lanyards, or harnesses

While ‘straddling’ beams is an approved method when carried out in conjunction with fall protection methods, it’s only permissible for ‘specific short-duration jobs where the beam is of an I beam section’.

Steel erectors should also ensure they’re sitting astride the flange, with both feet resting flat on the bottom flange and their hands either side of the top flange.

2. Materials being dropped

Challenge

Steel erectors require a wide range of materials and tools to carry out their responsibilities.

This can include everything from weighty impact wrenches to sharp grinders and even welding equipment – all of which can result in significant injury if dropped from above.

Solution

To help prevent injury to other steel erectors and trades working on the site, steel erectors should consider:

- Organising schedules to avoid trades working underneath the erectors

- Adding barriers to open edges (e.g. toe boards) to stop materials being pushed off

- Storing materials securely to prevent falls

3. Being struck by moving steel members or decking packs

Challenge

A core component of a steel erector’s role is controlling lifting operations, allowing them to accurately guide steel members and decking packs into place. Due to the significant weight and size of these moving objects, it’s particularly important to prevent other site workers from being struck.

Solution

The risk of being struck by moving steel components can be reduced by:

- Improving both individual and wider team competency

- Introducing exclusion zones to keep workers away from areas of high-risk activity

- Ensuring these objects aren’t being lifted over other site workers

4. Unintended structural collapse

Challenge

During the construction stage of a building or similar structure, maintaining integral stability at every stage of the erection is crucial. Failure to do so can lead to worker injuries and fatalities as well as substantial damage to property and equipment, resulting in both financial and legal implications.

Solution

To decrease the likelihood of unintended collapse, steel erectors should consider taking the following steps:

- Liaising closely with the project’s frame designer and/or a structural engineer

- Implementing the sequential method of erection to ensure structural stability

- Adding bracing, guys or stays into the design specifications

- Carrying out regular inspections of the structure’s integral stability at every stage

5. Manual handling

Challenge

Steel erectors commonly lift, carry, and handle items of significant weight, such as pipework, scaffolding, and various tools. Poor manual handling practices can not only result in personal injuries such as back injuries, strains, and sprains, but in the event of an accident, can endanger other workers, too.

Solution

Fortunately, steel erectors can reduce the risk posed by manual handling by:

- Carefully planning the erection sequence during the pre-construction stage

- Considering manual handling aids (cranes, trolleys, etc.)

- Improving competency by adopting proper lifting techniques

6. Cranes, MEWPS, and other equipment overturning

Challenge

The final steel erector health and safety challenge is ensuring the safe use of cranes, MEWPs, and other equipment often used by steel erectors, like tower scaffolds.

Due to the size, cost, and weight of this equipment, tipping and collisions can result in injuries and fatalities, or damage to equipment and property.

Solution

Steel erectors can play an important role in tackling site equipment collisions and tipping accidents by:

- Carrying out regular equipment checks and maintenance

- Ensuring the ground is strong and stable enough for the equipment

- Organising site traffic accordingly to help prevent collisions

Move your steel erector career forward

Due to the high-risk nature of this type of work, having a clear understanding of steel erector health and safety is essential – especially for those aiming for senior or supervisory roles.

That’s where our qualified instructors and assessors at SB Skills Solutions can help.

Our team of qualified instructors and assessors can support you in achieving your ECITB Level 3 Diploma in Steel Erecting. This nationally recognised qualification enhances your understanding of workplace hazards, strengthens your safety practices, and ensures compliance with the latest regulations.

Whether you’re looking to:

- Increase your earning potential,

- Broaden your job prospects, or

- Transition into leadership roles,

…this Level 3 steel erecting diploma offers a clear path forward.

To discuss applying for your Level 3 Steel Erecting Diploma in Engineering Construction: Lifting, Positioning, and Installing Structures, Plant, and Equipment, as an individual or on behalf of your employees, get in touch with our team today via email at info@sbskills.co.uk or by giving us a call on 01695 558 420.

Let’s build a safer, stronger future together.